Product Details

+

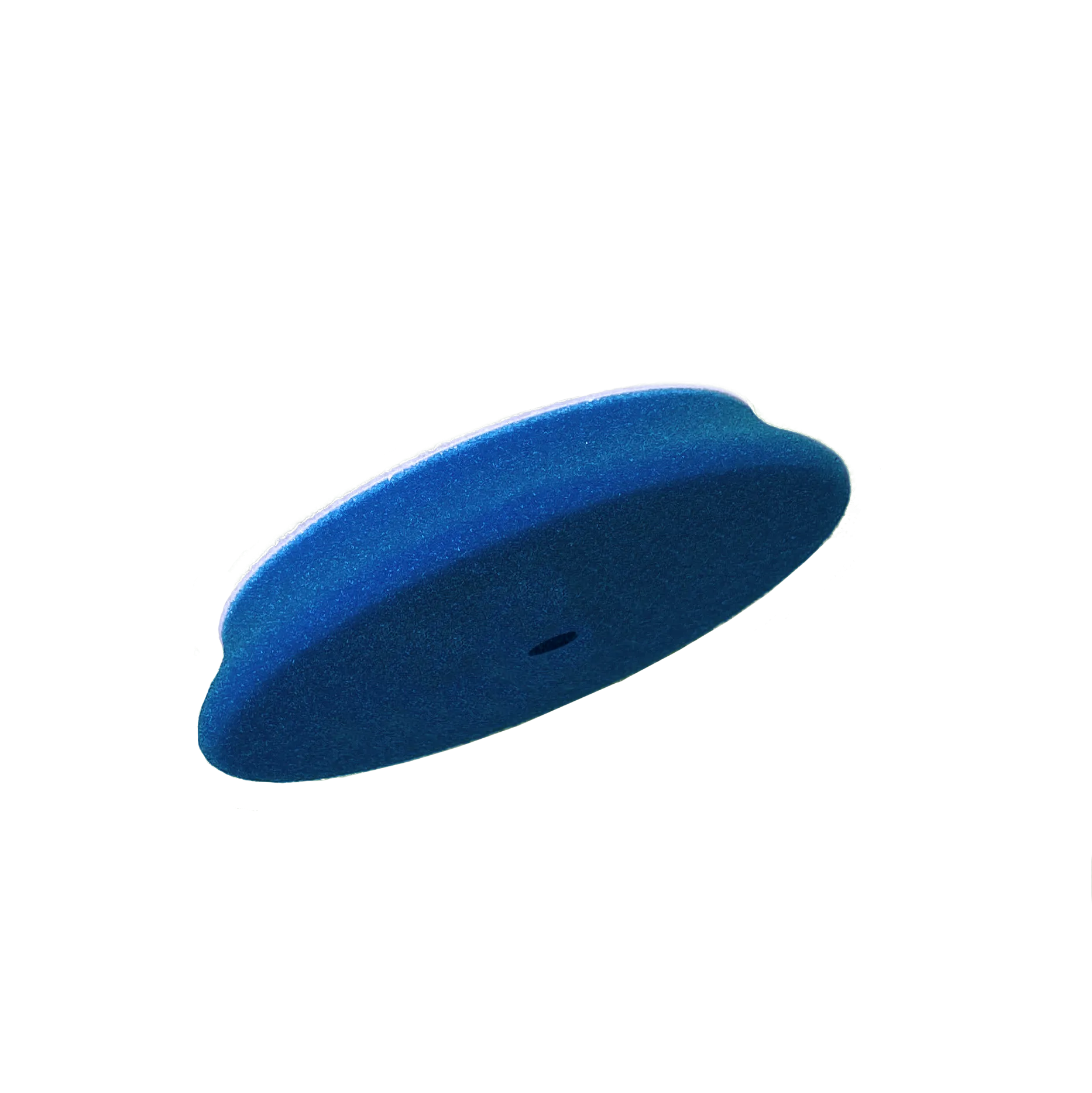

The DA COARSE foam pad is specially designed to be used with both random orbital and gear-driven tools. The unique open-cell all new foam material removes mild to severe defects from most paint systems. When paired with RUPES DA-COARSE compound provides improved cutting and finishing ability.

This new pad combines the best aspects of the previous blue and green foams, with an increased durability and a more vibrant blue color.

The result of years of research, testing, and development, the new RUPES D-A foam pad range offers increased performance, versatility, and optimized user experience. Developed specifically to compliment the high-performance D-A compounds, these innovative new pads feature proprietary foam formulas and a patented contour edge design which have been extensively tested and optimized for both gear-driven and random orbital tool movements. The reduced pad height, combined with the all-new foam materials, optimizes the transfer of energy from the tool to the application surface for more effective defect removal and higher quality finishing. The contour edge design has been strategically designed to maintain safe operation near edges. Additionally, the new pad profile improves the consistency of pad movement in curves and contours by reducing pad distortion. With every adjustment to the pad materials and design, RUPES engineers and product development specialists carefully considered the operator experience to ensure users would realize increased stability, performance, and ease of use. The new RUPES D-A foam pads represent the next step in the evolution of polishing pad performance for all orbital tools.

This new pad combines the best aspects of the previous blue and green foams, with an increased durability and a more vibrant blue color.

The result of years of research, testing, and development, the new RUPES D-A foam pad range offers increased performance, versatility, and optimized user experience. Developed specifically to compliment the high-performance D-A compounds, these innovative new pads feature proprietary foam formulas and a patented contour edge design which have been extensively tested and optimized for both gear-driven and random orbital tool movements. The reduced pad height, combined with the all-new foam materials, optimizes the transfer of energy from the tool to the application surface for more effective defect removal and higher quality finishing. The contour edge design has been strategically designed to maintain safe operation near edges. Additionally, the new pad profile improves the consistency of pad movement in curves and contours by reducing pad distortion. With every adjustment to the pad materials and design, RUPES engineers and product development specialists carefully considered the operator experience to ensure users would realize increased stability, performance, and ease of use. The new RUPES D-A foam pads represent the next step in the evolution of polishing pad performance for all orbital tools.